Introduction

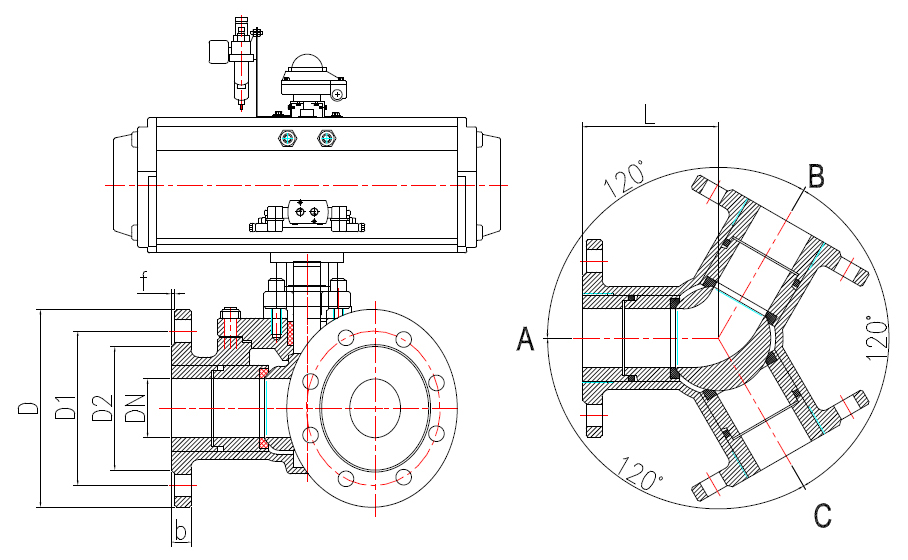

The flow channel form of this ball valve is 120-degree switching with large flow capability and minimum flow resistance.

Features

1. The flow channel is smooth and the flow capacity is strong, and the medium will not stay in the flow channel, so that each pipeline can be switched smoothly;

2. Various advanced processes such as soft sealing, spray welding nickel-based alloys (hardness>HRC60), supersonic tungsten-cobalt alloys (hardness>HCR70) and special hardening materials can be used respectively;

Technical specification

|

PN ( MPa ) |

Shell |

Seat(water) |

Seat(air) |

|

1.6 |

2.4 |

1.76 |

0.6 |

|

2.5 |

3.75 |

2.75 |

|

|

4 |

6 |

4.4 |

|

|

Class 150 |

3 |

2.2 |

|

|

Working conditions |

Applicable media |

Water, oil, gas and other non-corrosive media and acid-base corrosive media |

|

|

Operating temperature |

-28~350 ℃ |

||

|

Applicable Specifications |

Structure length |

EN558-1, ASME B16.10 |

|

|

connecting flange |

EN 1092-1, ASME B16.5 |

||

|

Inspection test |

EN12266-1 , API598 |

||

Size data

| DN | L | D | D1 | D2 | b | f | Z-Φ |

| 25 | 95 | 115 | 85 | 65 | 16 | 2 | 4*14 |

| 40 | 110 | 150 | 110 | 85 | 16 | 2 | 4*18 |

| 50 | 110 | 160 | 125 | 100 | 16 | 2 | 4*18 |

| 65 | 130 | 180 | 145 | 120 | 18 | 2 | 4*18 |

| 80 | 148 | 195 | 160 | 135 | 20 | 2 | 8*18 |

| 100 | 160 | 215 | 180 | 155 | 20 | 2 | 8*18 |

| 125 | 190 | 245 | 210 | 185 | 22 | 2 | 8*18 |

| 150 | 210 | 280 | 240 | 210 | 24 | 2 | 8*23 |

| 200 | 320 | 340 | 295 | 265 | 26 | 2 | 12*23 |

| 250 | 380 | 405 | 355 | 320 | 30 | 3 | 12*25 |

Contact: Zhang Heng (Bill )

Phone: 86 13634285240

Tel: 86 0577 86915200

Email: cspneumatic@hotmail.com

Add: Yongqiang High Technology Developing Zone, Wenzhou, China.