The pneumatic ball valve only needs to use the pneumatic actuator to rotate the air source by 90 degrees and a small torque to close tightly. The completely equal valve body cavity provides a low resistance, straight-through flow path for the medium.

It is generally considered that the ball valve is most suitable for direct opening and closing. It features compact structure, easy operation and maintenance, which is suitable for general working media such as water, solvent, acid and natural gas, and also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene.

It is requested by our customers to replace the existing valves with our brand. So we present the easy procedures to cope with the site maintenance as below.

1. Insert the bolts and tighten them

2. Mount the bracket

3. Fasten the nuts

4. Assemble the packing gland and tighten the nuts

5. Put inside the stem adapter

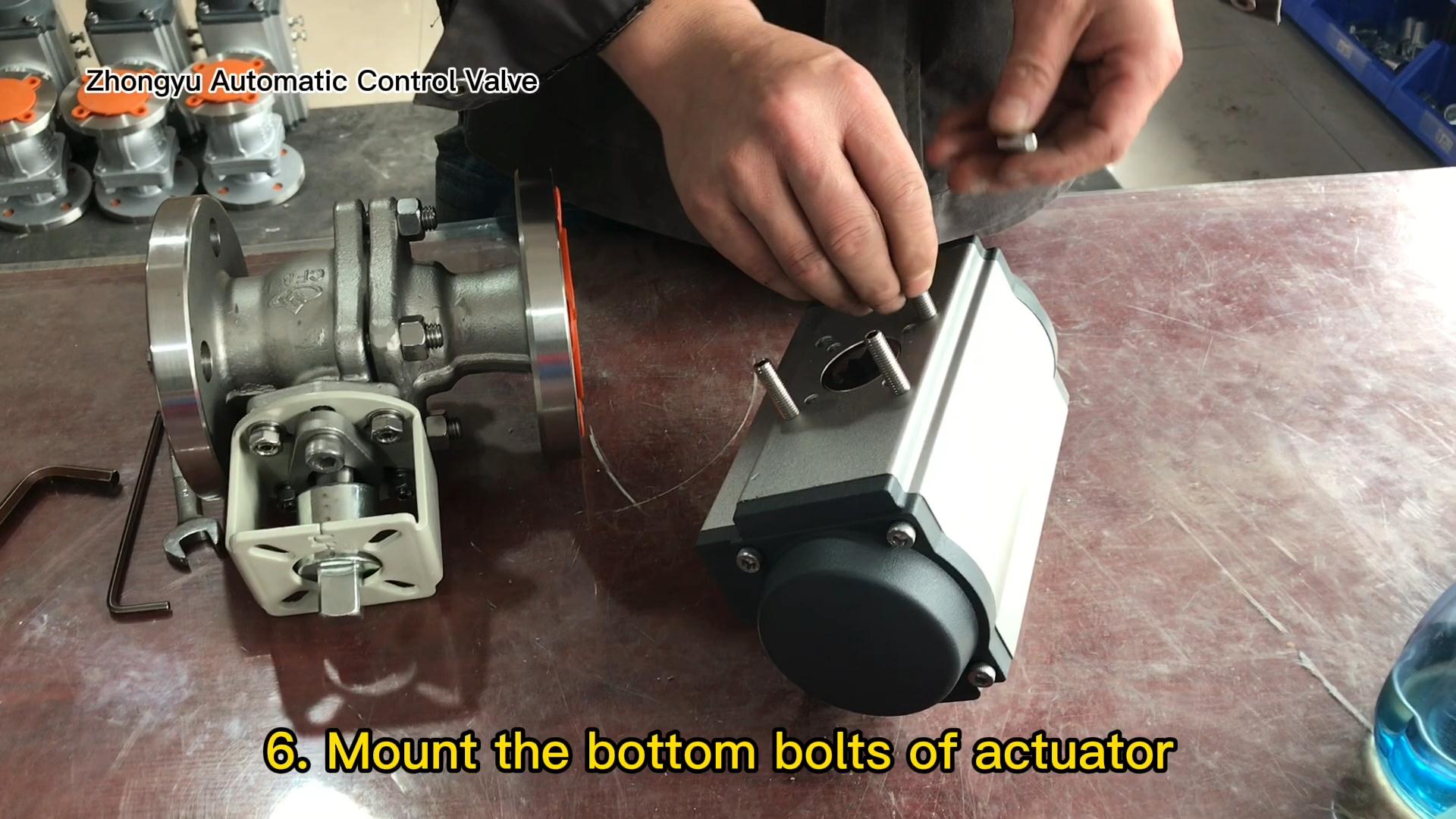

6. Mount the bottom bolts of actuator

7. Put the ball valve and pneumatic actuator together. Tighten bottom nuts.

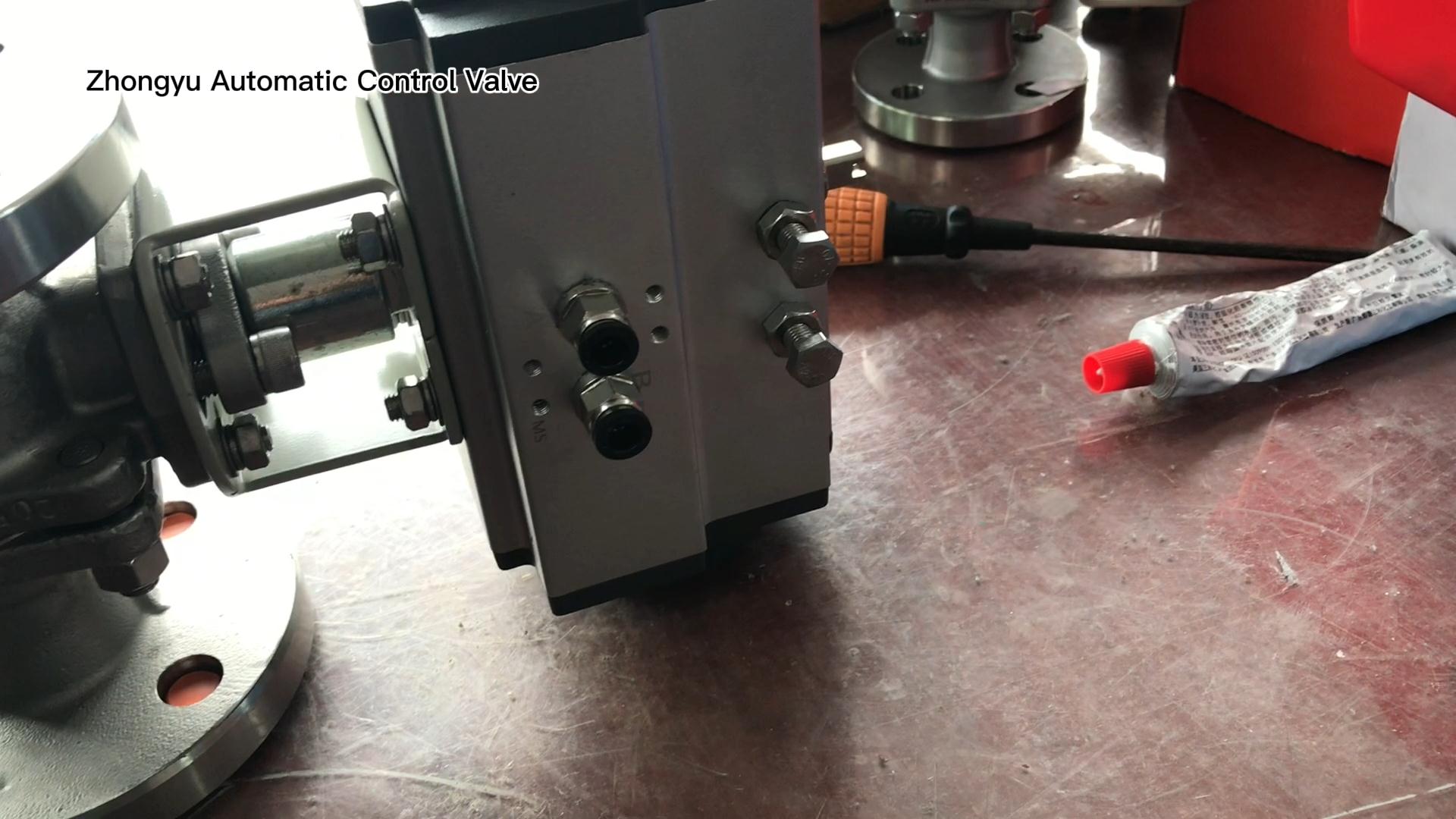

8. Mount the air inlet

9. Run the function test and check the ball movement

10. Attach the solenoid valve and air reducer

11. Do the function test with solenoid valve

For more details, please check our video on youtube

https://youtu.be/yHCAiWbSyaw

Contact: Zhang Heng (Bill )

Phone: 86 13634285240

Tel: 86 0577 86915200

Email: cspneumatic@hotmail.com

Add: Yongqiang High Technology Developing Zone, Wenzhou, China.